Wisdom Behind The Wood #4: Wood Movement

Welcome back to the fourth installment of Wisdom Behind The Wood! This month we’re covering wood movement. Almost all of us are familiar with a solid wood door sticking in the summer and rattling in the winter. This happens because wood 'moves', expanding and contracting with seasonal changes in temperature and humidity. Believe it or not, a solid wood dining room table top could be as much as ¼" wider during the summer than during the winter.

Why does wood move?

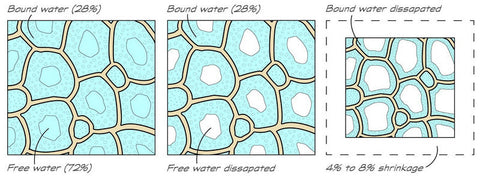

Wood is comprised of sponge-like cells that hold water. When a tree is felled and 'green', those cells are totally full of water. A commercial sawyer will typically cut green logs into slabs and then put the lumber in a huge kiln to remove most of that moisture, stopping when the moisture in the wood is equivalent to the moisture in the ambient air outside. But just like a sponge, wood cells will still absorb moisture and shed moisture. So when it’s warmer and wetter, the wood cells will fill with water and swell, and when it’s colder and dryer, the cells will shrink as they shed moisture.

For those of you interested in further information check out this website. They go into detail on wood movement and their illustrations are excellent.

Why does that matter with butcher block?

End grain cutting boards are very susceptible to changes in moisture from the air and washing because they are almost entirely composed of exposed end grain. The pores in the end grain of wood exchange moisture with the air significantly quicker than the edge or face grain. As a result, unprotected end grain is likely to warp or crack over time. The only method of defending those wood fibers from the relative humidity in the air or the moisture from food/washing is to saturate those cell walls with mineral oil. The fibers swell significantly less with mineral board oil which physically prevents the moisture in the air from bonding. To protect the board from liquid moisture, the beeswax in our cutting board butter fills in all the pores on the surface of the board creating a hydrophobic layer that causes water to bead up and run off. This one-two punch makes our cutting board care kits the perfect solution to care for your Boardsmith cutting board over the years to come.

Butcher Block Care

First off, it is important to keep those cell walls mostly saturated with mineral oil. We often get asked what a good oiling schedule looks like and it varies widely due to usage, washing method, and climate. Mineral oil dries at a very slow rate so baseline most unused cutting boards need to be oiled about every 30 days. Usage will shorten that timeline with washing having the biggest impact. Dish detergents like Dawn actively strip the oil out of the butcher block. This doesn't mean you shouldn't use dish detergent for a big mess, instead it means that you need to replace the oil stripped away during washing. John goes into further detail on washing and some tips and tricks in this video. Additionally, if you live in a dry climate, such as Colorado or Arizona, you will need to apply more oil to compensate for the shortened drying time of mineral oil. In general, you need to apply more mineral oil than you think. A 16" X 22" X 2" Carolina Cut Maple End Grain Cutting Board can hold up to 12 oz of oil when first oiled.

It is equally important to treat both sides of an end grain cutting board the same. Equal exposure to air, moisture, and oil will help to keep the wood fibers in equilibrium. Upon receiving a Boardsmith Board it is important to oil the board to saturation. It takes multiple floodings for the oil to work its way through the board. Most often when boards warp it is because the faces of the board unequally experience one of those three things. We strongly encourage the use of feet on the board as it will ensure adequate ventilation to both the top and bottom face. If you do experience a warp, don't panic as there is usually a simple solution. In order to correct the warp you need to water the "bowl" side or concave side lightly (~5 seconds under a tap) with room temperature water and place the board on the edge to dry. Once the warp has been corrected, it is important to heavily oil the board to prevent further warping. Additionally, make sure to adjust your butcher block care schedule with more frequent oilings as necessary.

Unlike many butcher block makers (especially the big ones), we take a number of specific steps in our construction methodology to mitigate the effects of wood movement. The end result minimizes the problems our customers will have over the years. Come back next month to learn more about our joinery and how it makes our block truly an heirloom piece.

About Nolan Russell

Nolan Russell is the Operations Manager at The Boardsmith. His blog segment dives deeper into the trees, lumber, and the science that make our butcher block the best in the world. Nolan is a Certified Arborist, former Tree Care Professional, and all-around tree nerd.